Marine FAQs

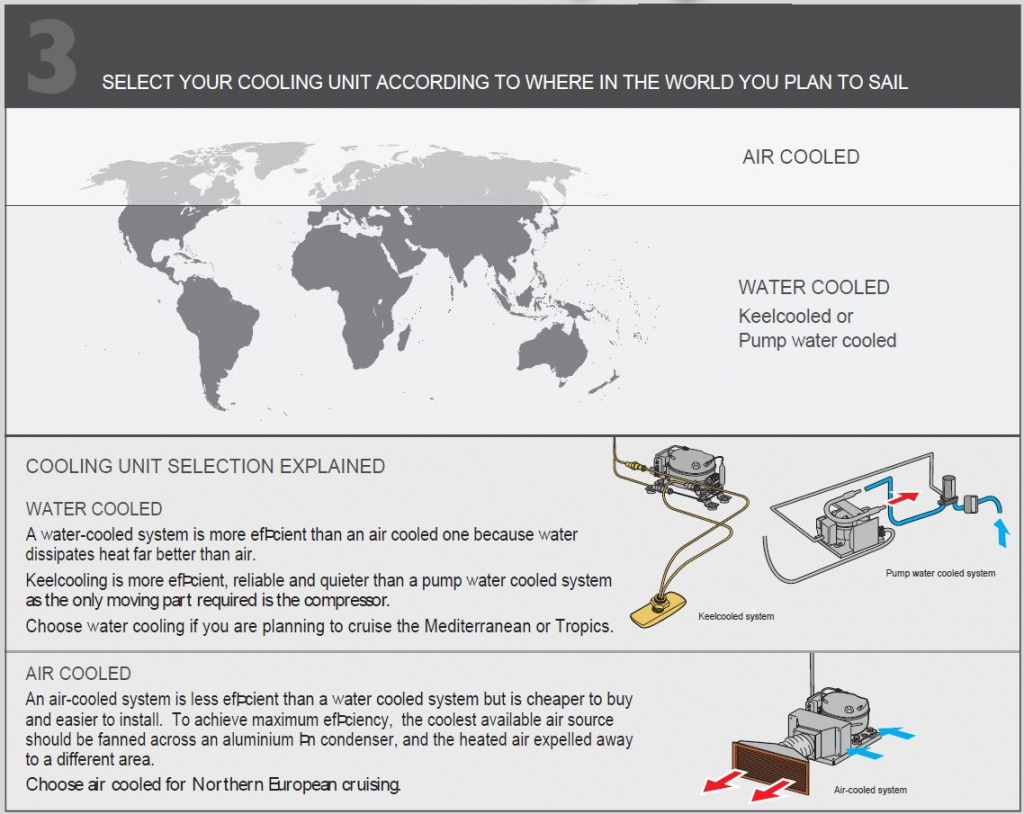

Need help confirming whether you need an air cooled, keelcooled or pump water cooled condenser?

Select your compressor and condensing unit according to where in the World you plan to sail and how efficent you want your system to be.

Choose Water Cooling if you want the most efficient system possible or are planning to cruise the Med or the Tropics.

Water cooling is the most efficient condensing unit available because water dissipates heat far better than air (some 20x more effective).

Keelcooling is the most efficient and reliable system of all as it uses water to cool the refrigerant but requires no pump so the only moving part is the compressor. With no fan or pump the keelcooler is also the quietest marine refrigeration system available.

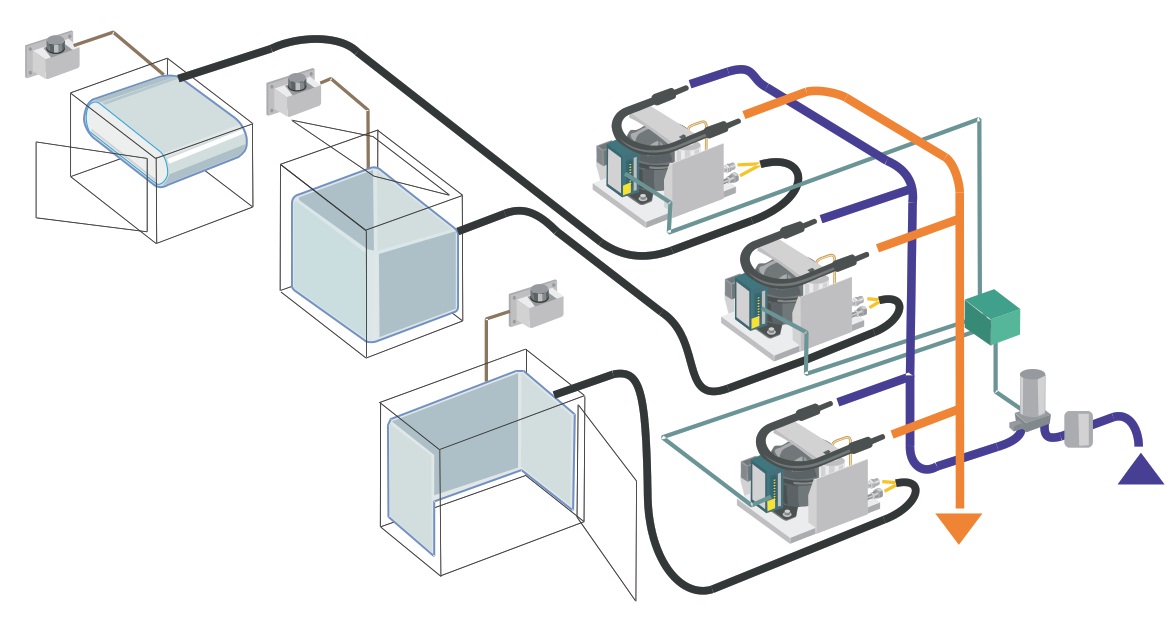

Pump Water Cooled is best suited for multiple fridge and freezer systems where one pump can be used with up to three compressors.

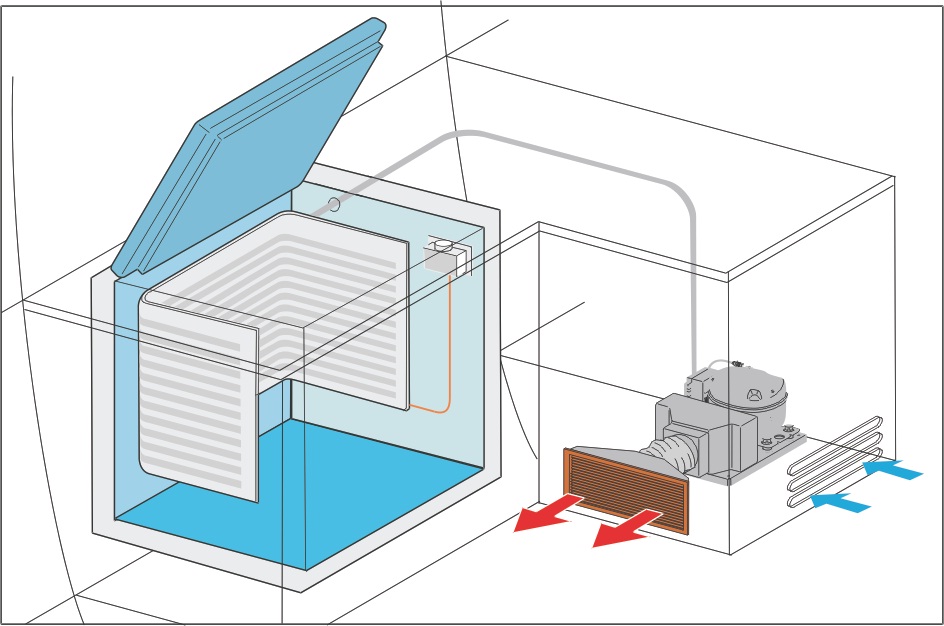

Choose Air Cooled for Northern European cruising

An air cooled system is less efficient than a water cooled system but is cheaper to buy and easier to install. To achieve maximum efficency from an air cooled system the coolest air source available should be fanned across an aluminium finned condenser and the heat expelled away to a different area.

Frigoboat supply a wide range of air cooled compressors. The higher the compressor’s maximum fridge capacity the bigger and better the aluminium forced air condenser.

Compressor sizing

Each compressor is rated to a maximum fridge or freezer capacity. For a fridge up to 200 litres a Danfoss BD35 compressor is likely to be the best choice. For larger fridges and all freezers a bigger capacity compressor is always preferred, so where the plate will support it we always recommend a Danfoss DB50 compressor.

Speed settings

Both the BD35 and BD50 have four speed settings allowing you to optimise the compressor to the fridge or freezer application. All the evaporator plates have a recommended compressor size and speed in the technical data.

Need help deciding on cabinet options and choices?

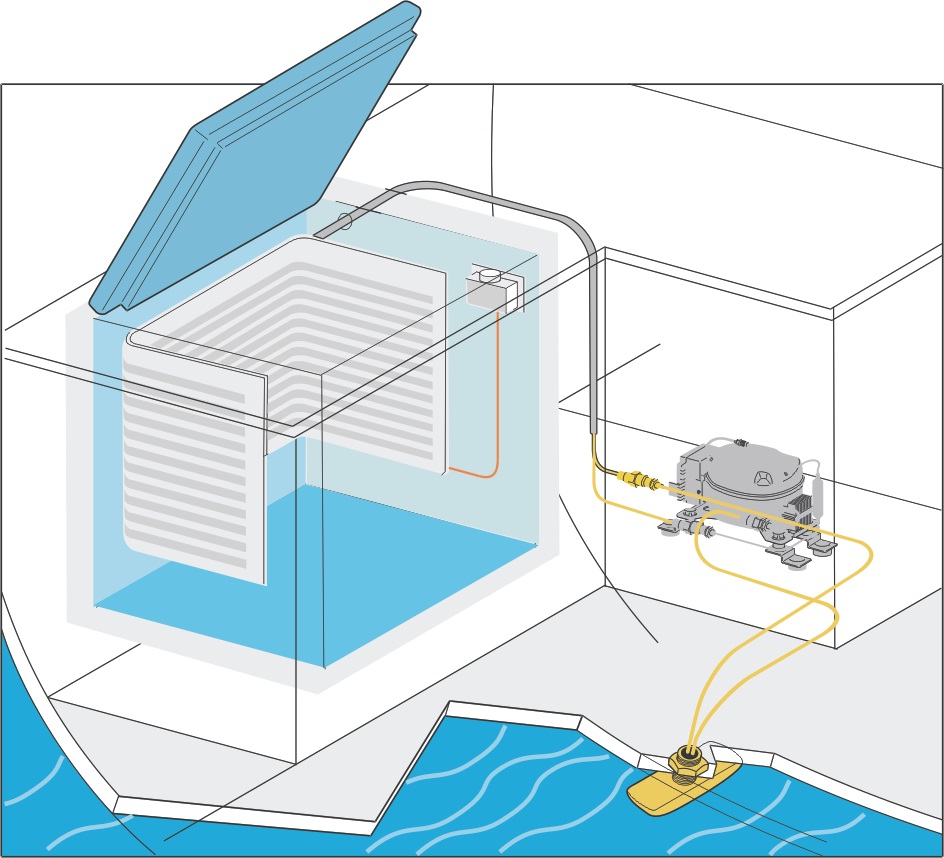

Fitting a keelcooled fridge system

The Keelcooler uses the water on the outside of the hull to cool and condense the refrigerant.

- Produced in marine bronze the sintered plate protects the heat exchanger from damage

- Sintered bronze is porous so the water passes through to the heat exchanger inside

- The heat exchanger is manufactured from cupro-nickel for maximum resistance against sea water corrosion.

- Supplied with sacrificial zinc anodes as standard for further protection from galvanic corrosion.

Technical Information:

- Dimensions 175 W 22 H 70 D (mm)

- Weight 2 (kg)

Through the action of the compressor, the hot, high pressure refrigerant gas is circulated through the keel cooler where it is cooled & condensed into a pressurised liquid that is then fed to the evaporator (in the insulated box). In the Evaporator plate it is allowed to expand & evaporates (boils) at a very low temperature before being pulled back to the compressor as a low-pressure gas, where the cycle begins again.

Installation of the Frigomatic Keelcooler

This must be mounted through the hull, below the waterline, by drilling a (38mm) hole (a 1.5″ hole may be used, carefully enlarging it, if necessary). Special constraints and working practices apply when installing the keel cooler on a vessel with a cored, metal, or carbon fibre hull. For these applications we suggest you consult a marine professional.

Recommended Fitting Instructions

- Decide where the keelcooler is going to be positioned.

- Drill a pilot hole where the keel cooler is to be located – from the inside out to avoid hitting any stringers etc.

- For boats with double skins, if when drilling, there is a clear gap between the inner moulding and the hull, use a 4″ hole saw to cut away a large enough section of the inner moulding to fit the keel cooler directly to the outer laminate. If there is no gap between the inner moulding and the hull and the two are completely bonded together drill straight through both laminates with a 38mm hole saw.

- Scrape away any existing antifouling so you are back to the bare hull to bond to.

Then drill a slightly oversized hole (38-40mm) so the keel cooler will easily slide up through. (it is a good idea to do a dummy run on a piece of wood to confirm).

- Once you have done your test, drill the hole in the hull, fit the O ring and insert the keelcooler from the outside.

- To hold it in place wind the nut on a couple of turns of the thread, so the washer holds it hanging down from the hull.

- Mask the keelcooler so just the surface to be bonded to the hull is exposed.

- Pull the O ring up and fill the recess with your waterproof adhesive

- Then drop the O ring onto the adhesive and add more adhesive on top of the O ring and the rest of the top surface of the keelcooler.

- Then with someone on the outside to hold the keelcooler in the correct orientation, push the keelcooler up flush to the hull and tighten the nut inside.

- Once in place just a ‘good nip’ with the spanner will hold it all in place until the adhesive has gone off and the keelcooler will then be bonded in place.

Grounding and cleaning the Keel Cooler:

Provision is provided for a grounding/bonding wire to be attached. It is very important that the Keel Cooler is electrically connected to the battery negative, with no switch in the circuit between the Keel Cooler connection and the battery negative.

If the Keel Cooler being installed is the type without zincs, it must also be connected to the vessel’s bonding system and a sacrificial zinc anode. This is an important safety precaution and a connection must be made to the battery negative whether the keel cooler has zincs or not.

The keel Cooler should not be painted and must be inspected periodically for corrosion. Clean occasionally with a brush, never with a metal scraper.

Location and Installation of the Compressor:

The compressor unit must be mounted within 1.5m of the keel cooler – this dimension cannot be extended. It must be mounted on a horizontal surface in an area where it will not be susceptible to physical or water damage, it does not need to be ventilated but should be accessible for service.

An anti-vibration mounting kit is supplied with the compressor that includes rubber mounts and steel inserts. The unit may be either screwed or bolted down using the supplied white, plastic washers. Alternatively, a Bulkhead Bracket can be used, in which case remove the stainless steel mounts from the compressor locating the unit to the bracket using the Teflon feet.

Installation of the Evaporator Plate

The evaporator has approximately 2.8m of copper tubing attached, with dust-plugs in the end fittings that must remain installed until the very last moment when the connections are ready to be made. A 30mm needs be drilled in the wall of the icebox. Carefully unroll the copper tubing, feeding it through to the area where the compressor & keelcooler is located. Some evaporators have sections of aluminium tubing close to the body of the evaporator that must be handled very carefully. Warnings to that effect are attached to the evaporator.

If the plate needs bending Penguin will do this for you if you supply a dimensioned drawing. The section of insulation that is free to slide on the tubing should be positioned starting at the point where the tubing exits the icebox. Do not add more insulation to the tubing.

Once the evaporator is installed, the exit hole in the box must be sealed with expanding foam, refrigeration putty, or other suitable material. Make sure that any drains are plugged and that there are no other holes or gaps through which air can enter the box. Any excess tubing may be carefully rolled up and fastened out of the way.

If the tubing is too short to reach the compressor / condensing unit, pre-charged extensions are available in 3, 6, and 10 foot lengths.